Cutter end mills are essential tools that help cut/shaper materials to the appropriate sizes and shapes. They are used in numerous settings, such as manufacturing plants and construction job sites where precision and speed are essential. As an example, workers utilize drill and bit sets to ensure that pieces mesh together face-to-face. Huazhichun, high quality cutter end mill manufacture. The tools that they create are made to be effective and fast, making it much easier for people to complete their tasks.

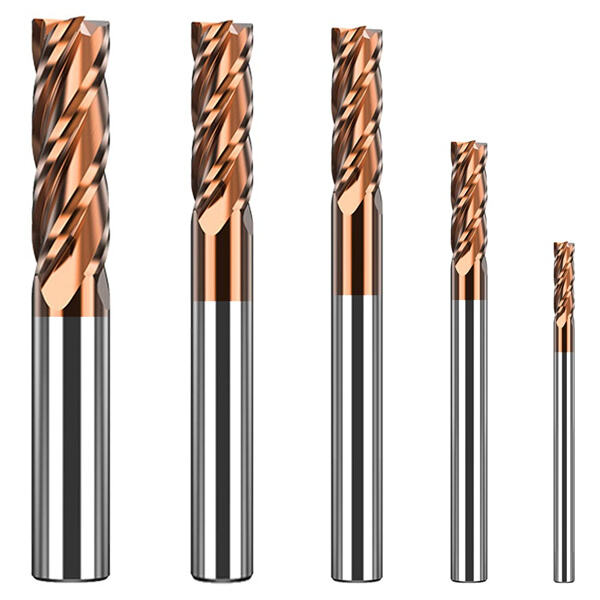

Cutter end mills are great because they can be used for many different applications. That means they are compatible with countless materials from metal to wood and plastic among others. Since they are available in different sizes and shapes, their use is able to cover several types of works. For example, if a worker is required to carve the wood in some particular direction than he can select the end mill cutter which is appropriate for that task ही.

An end mill cutter tool is a complex end mill and comes in different shapes for preparing shapes on a material. They can also make pockets(small holes), holes of any size and so much more complex designs that require special care. There are drill and drill bit sets particularly designed for each one of these purposes. That means that workers have the tools they need to create what is actually needed.

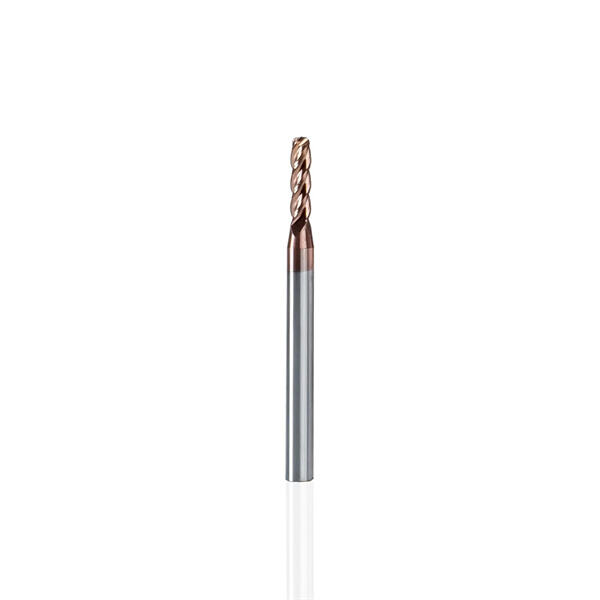

Different types of cutter end mills are made for distinct functions. For instance, cutters like flat bottom end mills are used for cutting materials on a flat surface. When a worker needs have a smooth and even surface, this is important. Ball nose end mills, meanwhile, are a great option for creating gentle curves and contours. These are typically utilized whenever a design needs to have more of a curvature and pleasant way.

To achieve proper abrasiveness the right cutter end mill is imperative to choose. There are a few considerations that you should take into account when choosing an end mill. To begin, determine the type of material you will be machining. End mills' cutter types vary depending on the material. Next, consider what you want to make and how to refine it. That also translates to determining the level of precision in design required, and if there is any tolerance allowed.

Another important thing is what kind of machine you need to be able to understand its speed. There are variations in machines which means the right cutter end mill needs to be matched up with the machine. The right cutter end mill helps you run more efficiently and productively while also ensuring that your tools have a longer life. Huazhichun has a large range of available cutter end mills, and so workers will be able to find a tool that suits a specific need.

Moreover, it is also essential to sharpen the end mills on time in order to keep their cutting edge. A sharp cutter end mill will perform better and more effectively than a dull one. In addition to these services, Huazhichun has also provided sharpening services that help your end mills stay sharp. A proper maintenance may take some time, however as a result it makes sure your tools are prepared for the next work.