Metal workers spend a lot of time manipulating and cutting the metal that they work with, often needing special tools. An end mill bit is one of the most valuable tools necessary to perform this task. Die — This is a very essential tool as it shapes the metal into desired forms. At the end, the end mill bit has a very sharp edge that is necessary because it cuts into the metal and creates various shapes or types of cut material.

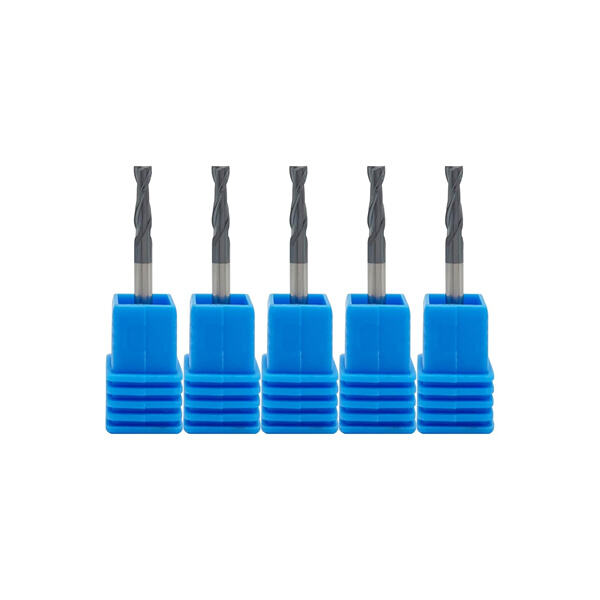

Well, actually end mill vary a great deal in both shape and size. They vary from tiny to enormous. They also can be made with different materials, so they are suited for specific jobs. Some of the bits, as an example, are made for slicing hard metals and also some slice softer steels. Their versatility makes them suitable for a variety of jobs.

They are compatible with various metal types including steel, aluminum and brass. This means that they are applicable to numerous projects. Endmill bits excel in producing grooves, slots, pockets and other. These bits will bring you a simple cut, or some complexity in the shape.

End mill bits are a great choice if you want to work better and also make your metal projects appear nicer! These bits are meant to make accurate cuts, allowing your work to be performed at a unparalleled degree of precision. If you are creating anything that must be assembled perfectly, like machine parts or tools, this is very important.

One more impressive feature of an end mill bits is that they are durable. These are created from powerful, sturdy materials that can withstand a lot of usage with out deteriorating. Which means you won not be purchasing new bits as much as you will with other tools. When you combine end mill bits in with your tools, it can be one of the best long-term investments that boost not only your pocket, but also make your shop run super-effective.

A brief background on what they are, is going to give you a better sense of how end mill bits actually work. An end mill bit consists of three components; the flute, shank and cutting edge. The bit has components, each with its own specific function to assist the bit in doing its job.

There are a few things that you should keep in mind while choosing an end mill bit. Before anything else, think about what kind of metal it is that you will be working with. After that you can consider the shapes and dimensions of the cuts which need to be made. Finally, think about just how accurate your cuts need to be for your project.