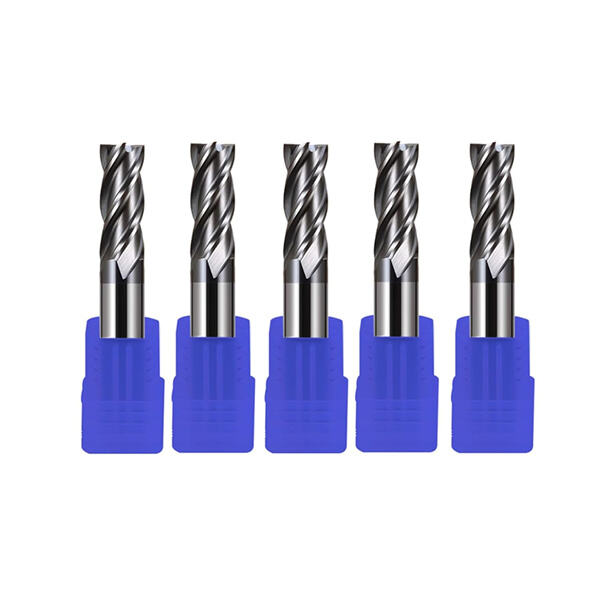

المطاحن النهائية الكربونية هي أدوات فريدة تم إنشاؤها لتساعد في تحقيق منفعة ما عن طريق قص المواد مثل المعدن و/أو الخشب. يمكنها إنشاء القصات والأشكال الأكثر دقة، وبالتالي تلعب دورًا حيويًا في العديد من الصناعات. إنها مقاومة جدًا، وهي مصنوعة من الكاربيد مع حواف حادة تُستخدم كأدوات قص. الكاربيد، الذي يتميز بصلابته الشديدة ومقاومته للحرارة العالية والبلى، يمتلك عمرًا طويلًا حتى تحت الاستخدام الشديد.

المطحنة النهائية الكربونية هي أداة قطع تُستخدم لإزالة المادة من سطح الأشياء. بمعنى آخر، إذا كنت بحاجة إلى تغيير شكل شيئٍ ما مثل قطعة معدنية أو خشبية، يمكنك استخدام رؤوس حفر كربيد لجعل ذلك يحدث. الكربيد هو مركب يتكون من الكربون، مع إضافة عناصر أخرى لصنع المواد المستخدمة في هذه الأدوات. إنها هذه المزيج الفريد الذي يمنح الكربيد قوته ومتانته. في الآلات، يمكن استخدام المطاحن النهائية لقطع، حفر أو حقن المادة لتصميم الجزء. بسبب العديد من المزايا لاستخدام مطاحن الكربيد مقارنة بالأدوات الأخرى، يتم تفضيل هذا الأداة من قبل العديد من العمال في مجالاتهم المختلفة.

صفة رائعة ثالثة للمناشير الكاربيد هي أنها تقطع بدقة كبيرة. أسلاك القطع الدقيقة لهذه الأدوات تسمح بتشكيل أشكال مختلفة بدقة وهي ضرورية في العديد من عمليات التصنيع. هذا يضمن أن إذا كان الأداة دقيقة، فإن المنتج النهائي سيكون صحيحًا. الحواف الحادة تعني أيضًا أنه يتطلب جهدًا أقل لتقطيع المواد. وهذا يمكن أن يسرع العمل مما يجعل عملية التصنيع أكثر إنتاجية وكفاءة.

المطاحن الكربونية أيضًا مرنة للغاية. يمكن تطبيقها لقطع مجموعة واسعة من المواد مثل المعدن، الخشب، البلاستيك وبعض المواد المركبة. هذه المرونة هي ما يجعلها شائعة الاستخدام في العديد من الصناعات، من تصنيع السيارات وصناعة الخشب إلى البناء الصناعي الكبير! يمكن استخدام المطاحن الكربونية لأغراض مختلفة لأنها قادرة على العمل مع مواد مختلفة، لذلك لن يضطر العمال إلى القلق بشأن أي أداة محددة هي الأنسب لمهماتهم.

على الرغم من وجود العديد من الفوائد مجموعة الحفر والبت ، إلا أنها تأتي أيضًا ببعض العيوب التي من الحكمة معرفتها. العيب الرئيسي هو السعر. بينما يعتبر الكربون مادة مكلفة مقارنة بالمواد الشائعة المستخدمة في المطاحن النهائية، مثل الفولاذ عالي السرعة، يأتي هذا بسعر مرتفع حيث أن المطاحن الكربونية تكون مكلفة في التصنيع والشراء. يمكن أن يؤثر هذا التكلفة الإضافية في قرارات الأعمال حول الأدوات التي سيعملون بها.

للمطاحن الكربونية أيضًا عيب الهشاشة. وعلى الرغم من قوتها، يمكن أن تتشقق أو تنكسر تحت بعض الظروف. على سبيل المثال، قد لا تتحمل بشكل جيد إذا تم تسخينها بشكل مفرط أو تعريضها لضغط زائد. وهذا يعني أنه يجب التعامل مع المطاحن الكربونية وتخزينها بعناية. تحتاج إلى اتخاذ رعاية خاصة لهذه الأدوات لتجنب تلفها مما قد يؤثر على أدائها.

تلبّي احتياجات التصنيع الحديثة من مطاحن الكربون Huazhichun. فهي تتميز بمقاومة عالية للتآكل، مما يسمح لها بالاحتفاظ بقدرتها على القطع لفترة طويلة. كما أنها ملائمة جدًا للدرجات العالية من الحرارة، وهو أمر حاسم للكثير من العمليات الصناعية. إذا كنت بحاجة إلى أداء قطع جيد في التطبيقات الجوية، الدفاع، الطبية، والسيارات - فهي مثالية لذلك - خصائصها ببساطة رائعة.